Silo Storage System Advantages Cement Storage: 5 Strategic Benefits for Construction Projects

Silo Storage System Advantages Cement Storage solutions are transforming how construction companies manage bulk materials. Cement is one of the most critical components in any infrastructure or building project, and improper storage can lead to moisture contamination, material loss, and operational inefficiencies.

Implementing a modern Silo Storage System ensures cement remains dry, protected, and readily available for production, improving overall project profitability and workflow continuity.

As part of a broader infrastructure and storage strategy, silo systems play a central role in optimizing supply chains and maintaining consistent material quality across demanding job sites.

What Is a Silo Storage System for Cement Storage?

A Silo Storage System is an engineered solution designed for the bulk storage of cement and other powder materials such as lime, gypsum, and fly ash.

These systems protect cement from moisture and environmental exposure while allowing controlled discharge into mixers, batching plants, or transport equipment.

Modern silo configurations are built with:

- High-strength steel structures

- Moisture protection systems

- Dust control components

- Integrated loading and unloading compatibility

For industrial-grade performance and seamless integration with pneumatic transfer and bulk handling equipment, explore the engineered Silo Storage System solutions designed for demanding construction environments.

5 Key Silo Storage System Advantages for Cement Storage

1. Cement Quality Preservation

A properly designed silo prevents exposure to humidity and temperature variations. This ensures cement retains its chemical and structural properties, avoiding premature hardening or reduced performance.

Maintaining material integrity directly impacts concrete strength and long-term durability in infrastructure projects.

2. Higher On-Site Efficiency

Integrated discharge systems allow fast loading into mixers or bulk trailers, minimizing downtime and accelerating project timelines.

When combined with pneumatic transfer systems, cement flow becomes smooth and controlled, improving batching precision.

3. Reduced Operational Costs

By minimizing material loss and optimizing transport logistics, silo storage reduces labor intensity and unnecessary handling expenses.

According to industrial safety and material handling standards promoted by organizations such as OSHA (Occupational Safety and Health Administration), proper bulk storage significantly reduces dust exposure and operational hazards.

https://www.osha.gov/

4. Safety and Sustainability

Modern Silo Storage Systems reduce airborne cement dust, improving worker safety and environmental compliance. Controlled storage and discharge contribute to cleaner, more organized job sites.

5. Operational Versatility

Different silo designs adapt to project requirements, from temporary mobile worksites to permanent high-capacity concrete plants.

Types of Silo Storage Systems for Cement Storage

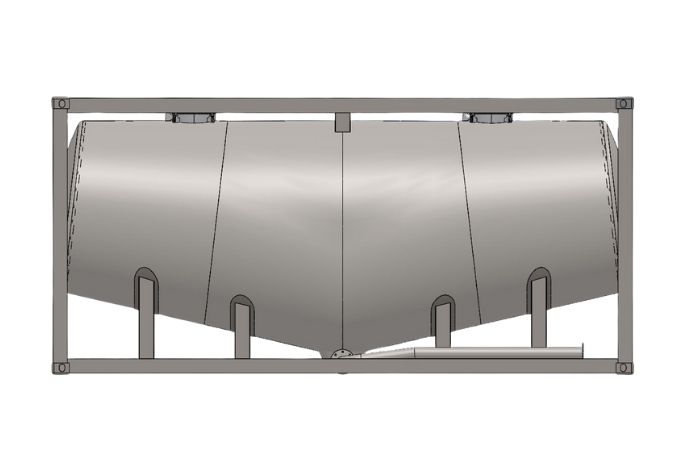

Container Silo

Portable silos built in container format provide flexibility and easy installation without extensive civil works.

Advantages:

- Rapid setup

- Ideal for short- or mid-term projects

- Flexible storage capacity

- Easy relocation

Trailer Silo

Mobile silos mounted on trailers offer transport and storage capabilities in a single unit.

Advantages:

- High mobility between sites

- Capacity up to 23 m³

- Integration with pneumatic unloading systems

- Ideal for dynamic infrastructure projects

Bolted Silo

Modular bolted silos are engineered for permanent installations in industrial facilities.

Advantages:

- Large storage capacity

- Heavy-duty structural durability

- Suitable for ready-mix and precast plants

- Long-term operational stability

For more industry insights on storage and infrastructure solutions, visit our Infrastructure & Storage category where we explore advanced systems and applications.

How to Choose the Right Silo Storage System

Selecting the correct configuration depends on three main factors:

Project Duration

Temporary worksites benefit from container or trailer silos.

Permanent facilities require bolted silo installations.

Required Cement Volume

Under 50 tons → container silo

50–100 tons → trailer silo

Over 100 tons → bolted silo

Logistics and Mobility

Frequent relocation → trailer silo

Fixed industrial plant → bolted silo

Proper evaluation of these factors ensures maximum return on investment and operational efficiency.

Practical Applications of Silo Storage Systems

Silo Storage Systems are widely implemented in:

- Road and bridge construction

- Ready-mix concrete plants

- Large-scale infrastructure projects

- Remote worksites with limited supply logistics

- Industrial cement processing facilities

Their ability to preserve cement quality while maintaining controlled discharge makes them a strategic component of modern construction supply chains.

Why Silo Storage System Advantages Matter for Large-Scale Projects

Understanding Silo Storage System Advantages is essential for contractors managing high-volume cement demand. These advantages directly impact productivity, material preservation, and overall project performance.

When companies invest in solutions that prioritize durability and moisture protection, they fully leverage the Silo Storage System Advantages that modern infrastructure projects require.

Conclusion: The Strategic Value of a Silo Storage System

Investing in a Silo Storage System goes beyond basic cement storage. It enhances productivity, reduces waste, ensures compliance with safety standards, and strengthens the overall efficiency of construction logistics.

As projects increase in scale and complexity, secure and controlled cement storage becomes a competitive advantage.

If your goal is to improve bulk cement management and operational reliability, explore engineered silo solutions tailored to your project requirements.

Recent comments