This equipment is highly versatile and ideal for cement big bag unloading, transferring material into bulk trailers, or integration with pneumatic transfer systems. With its low power consumption of 5 kW and easy installation process, it offers a highly efficient solution for industrial bulk powder handling.

The system features a 3.92cy (3 m³) capacity with a discharge rate of up to 45cy/h (35 m³/h) and a discharge height of up to 14′. It is equipped with an 8″ diameter by 20′ vertical screw conveyor, a side vibrator, and a CE-certified electrical control panel. For enhanced safety and accessibility, the unit includes telescopic legs and stairs with safety rails. Optional features, such as an integrated 150 sf dust collector and a telescopic bellow, are also available to further ensure a clean work environment.

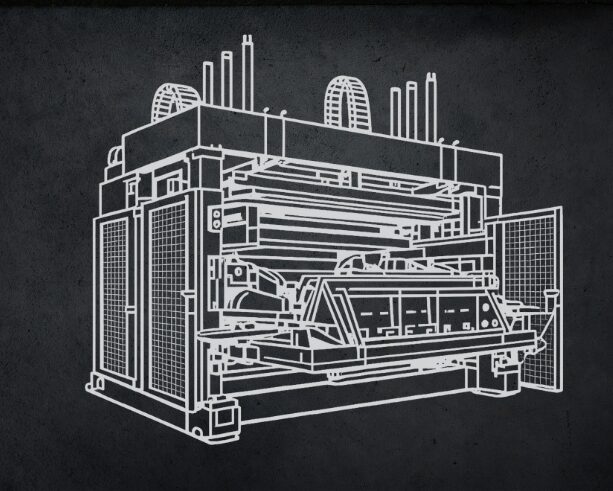

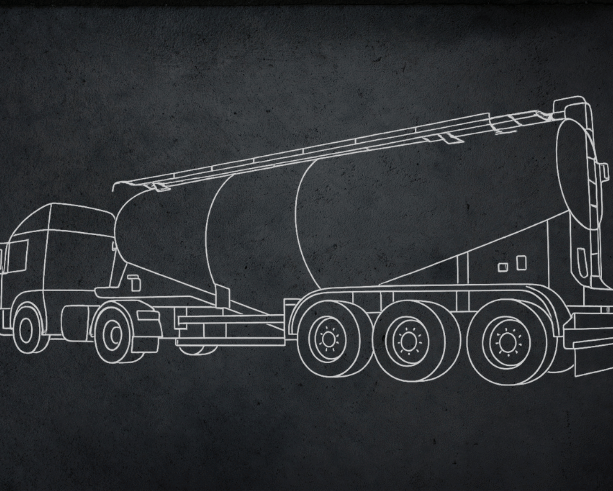

Big Bag Breaker Stark

The Stark Big Bag Breaker is designed for the safe and efficient unloading of cement Big Bags, using a vertical screw conveyor that ensures a steady and controlled material flow. By allowing direct discharge into storage silos or cement bulk trailers, the unit significantly reduces waste, dust emissions, and on-site operational risks. Built from carbon steel S235JR/S275JR, with a side vibrator and integrated dust collector and Below, it ensures a clean, reliable and low-maintenance process.

Key Features

- Capacity: 3.92cy (3 m³)

- Discharge rate: up to 45cy/h (35 m³/h)

- Discharge high up to 14′

- Vertical screw conveyor unloading 8″dia x 20′ (Ø 219 mm x 6,000 mm)

- Carbon steel S235JR/S275JR construction

- Optional: Integrated dust collector 150 sf (14 m²)

- Optional: Telescopic bellow

- #3 Telescopic legs and stairs with safety rails

- CE certified electrical control panel

- Approx. weight: 2,840lbs (1,300 kg)

Applications

- Cement Big Bag unloading into storage silos.

- Transfer of material into cement bulk trailers for transport.

- Industrial bulk powder handling processes.

- Integration with pneumatic transfer systems (Cement Blower).

Benefits

- Efficient and continuous Big Bag emptying.

- Controlled discharge via screw conveyor.

- Compatible with silos and cement bulk trailers.

- Dust reduction with integrated collector.

- Easy installation and low power consumption (5 kW)

FAQ – Big Bag Breaker

01. Where can the Big Bag Breaker unload cement?

It can unload cement from Big Bags into storage silos or cement bulk trailers.

02. How is the material discharged?

The system uses a vertical screw conveyor that ensures a constant and safe flow.

03. What maintenance is required?

Regular cleaning of the screw conveyor, filters and vibrator is recommended to maintain system efficiency.

Stark guidance for your next purchasing decision

At Stark we help you choose the solution that best fits your cement handling and storage projects. Our team provides the technical information you need to invest with confidence.